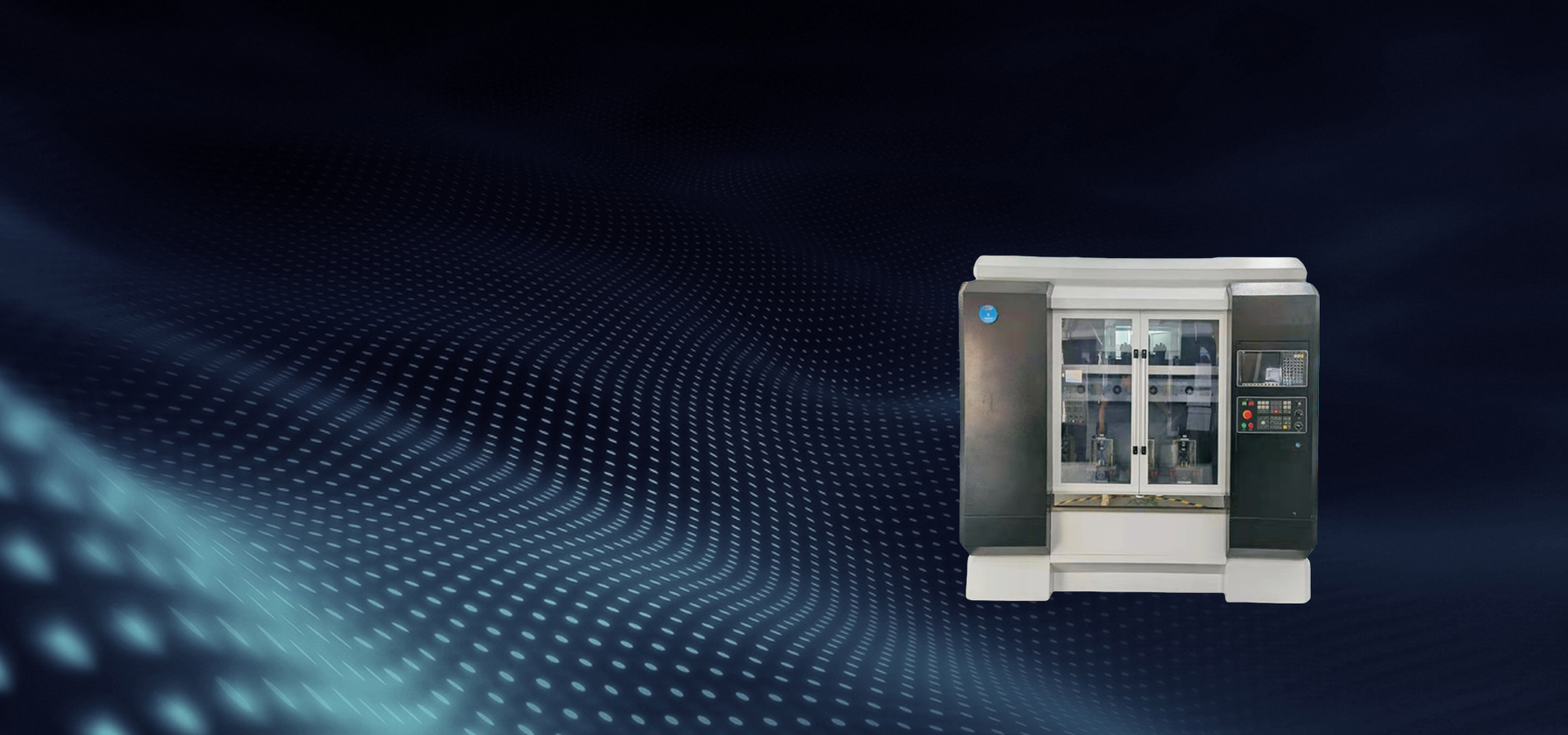

Model features

1. The equipment adopts a four sided electric spindle, with two sides being eccentric and two sides having nozzles, which can be installed

Rod type consumables

2. The equipment has 4 workstations that can be used for polishing and deburring various models of mobile phones, die-casting parts, etc

Automatic flipping and polishing

3. The equipment adopts force controlled sensing, and the pressure fluctuation can be controlled within 1N, which can be used for Y and Z axes

Two directions for force control compensation: 10mm,

4. The whole machine adopts stainless protection and can withstand strong acids and alkalis;

5. Doors and windows are equipped with safety devices, and opening doors and windows is prohibited during operation

6. The water tank is equipped with liquid level and flow alarm devices, and comes with mixing function

7. Central China system, five axis linkage

Basic parameters of machine tool

Model content | Parameter |

Grinding disc polishing wheel end face runout (static) (mm) | 0.05 |

Symmetry of Square Standard Block to Rotation Center (mm) | 0.05 |

Polishing work positions | 4. |

C1 axis rotation accuracy - cylindrical axis (mm) | 0.05 |

Workpiece speed range (r/min) | 0.5-300 |

X/Y/Z axis travel (mm) | 360/400/300 |

Small Y-axis stroke (workpiece compensation axis) (mm) | 10 |

Small Z-axis stroke (workpiece compensation axis) (mm) | 10 |

Processing workpiece size range (inches) | 3~8 |

X/Y/Z axis repeat positioning accuracy (mm) | 0.005 |

C1 axis repeat positioning accuracy (arc minutes) | 1. |

Polishing head speed (r/min) | 100-6000 |

voltage | AC 380V |

total power | 20KW |

Air pressure demand | 0.6MPa |

Water/polishing solution | Recycle |

Dimensions (length * width * height mm) | 2100*2200*2300 |

Equipment weight (kg) | 3000 |