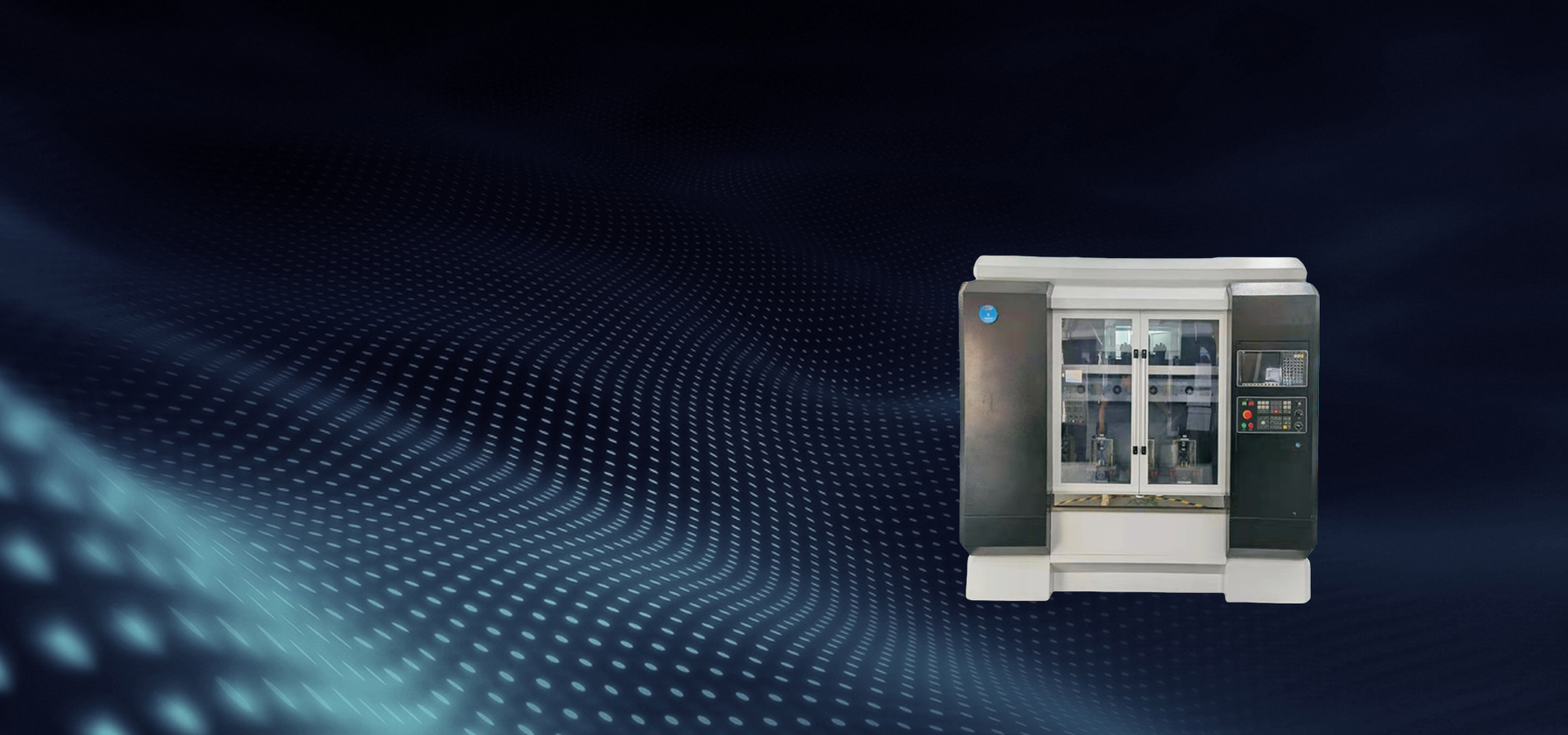

Model features

1. The equipment is equipped with a four sided electric spindle, which is concentric on all four sides and has two nozzles on both sides. It can be used to install rod-shaped consumables

2. The axis of workpiece A rotates independently, and each workpiece axis is driven to rotate by an independent motor, with a short transmission path

Ensure the precision of rotation

3. The large Y workbench can achieve front and rear movement of four workstations as a whole, while the small YX workbench can achieve front and rear movement of individual workpieces

Moving left and right, the small Y motor uses Yaskawa motor and Yaskawa drive, with timely response and reliable accuracy to ensure every one

Relative positional accuracy between workstation and grinding head

4. The outer surface of the workbench components is protected by an integral stainless steel shield, which is corrosion-resistant

5. Suitable for glass back camera, volcano crater polishing and grinding

Basic parameters of machine tool

Model content | Parameter |

Grinding function | Grinding and polishing |

Quantity of workpieces processed at once | four |

Continuously complete the process | 4 lanes |

A-axis rotation angle | -5°~+365° |

X/Y/Z axis travel (mm) | X:350 Y:350 Z:300 |

Small X/Small Y/(mm) | X:20 Y:20 |

X/Y/Z axis repeat positioning accuracy (mm) | ±0.02 |

C-axis swing angle | 360 degree continuous (-5 °~+365 °) |

voltage | AC 380V |

total power | 15KW |

air pressure | ≥0.5Mpa |

water | recycle |

Dimensions (length * width * height mm) | 2440X1980X2250 |

Applicable to products | Glass camera hole, volcanic crater |

Processing product dimensions | 55MM-310MM |

XYZ feed rate | 100-500mm per second |

control system | New generation system |

Electric spindle grinding head speed | 300-6000 |