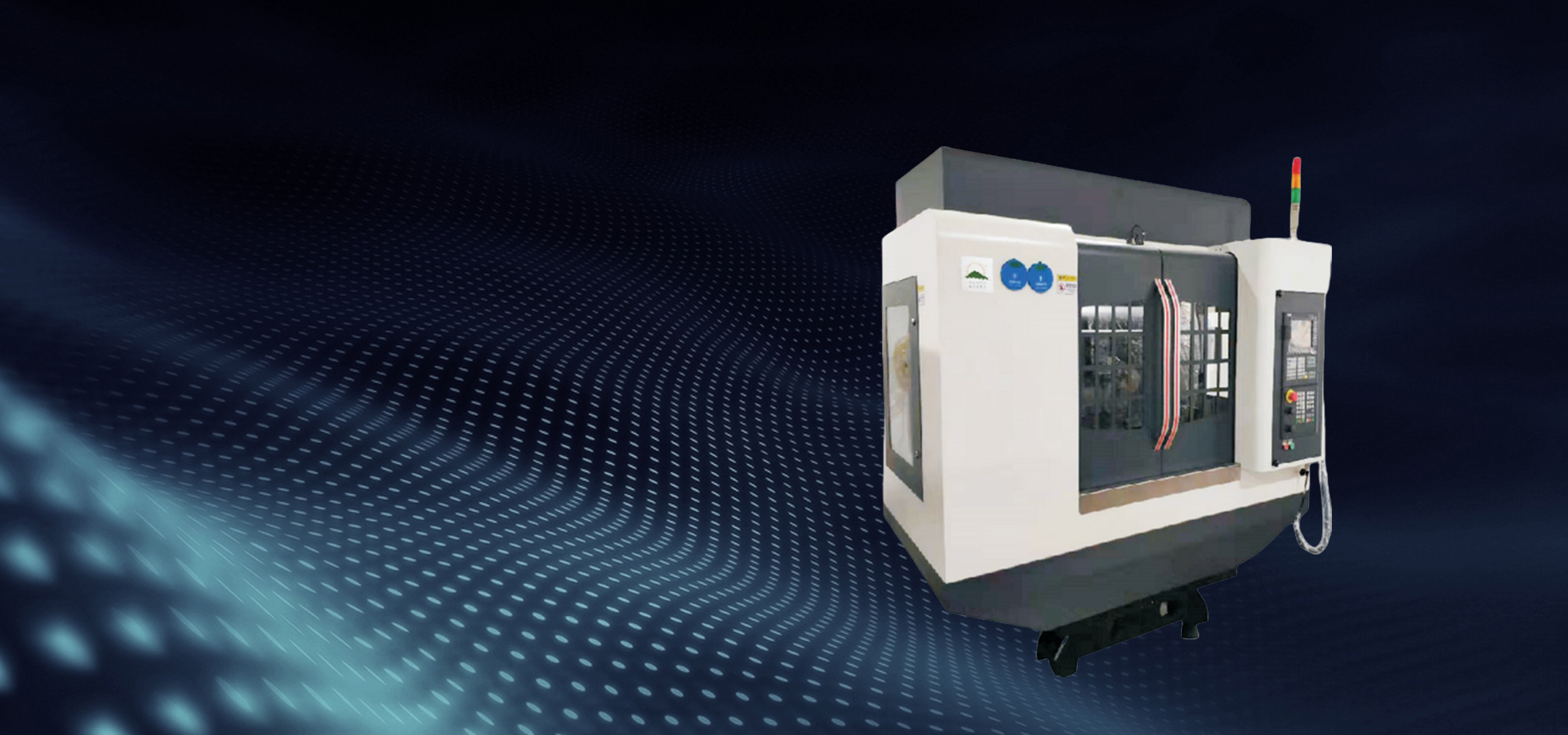

Model features

1. The equipment grinding head adopts a self-developed mechanical structure grinding head, and the four sides can be customized according to different requirements

The process requires the use of different polishing consumables;

2. Characteristics of gear ratio design for the mechanism: high torque, minimal wear on imported bearings, and low noise

3. It is widely used in ceramic rough polishing and bright polishing processes

The distance between A-axis (workstations) is 210m

Basic parameters of machine tool

Model content | Parameter |

function | Four sided circular grinding head |

Quantity of workpieces processed at once | five |

Continuously complete the process | 4 lanes |

A-axis rotation angle | -5°~+365° |

X/Y/Z axis travel (mm) | X:250 Y:400 Z:300 |

X/Y/Z axis repeat positioning accuracy (mm) | ±0.02 |

C-axis swing angle | 360 degree continuous (-5 °~+365 °) |

voltage | AC 380V |

total power | 9KW |

air pressure | ≥0.5Mpa |

water | recycle |

Dimensions (length * width * height mm) | 1950X1780X2250 |

Applicable to products | Ceramic backboard |

Processing product dimensions | 55MM-210MM |

XYZ feed rate | 100-500mm per second |

control system | Siemens/New Generation |

Japan Kamo Roller | CPA1610B-2B |

Japan Kamo Gear | CRA1610A-2BF-L992 |

Mechanical grinding head speed | 2000RMP |

Equipment weight | 2800KG |